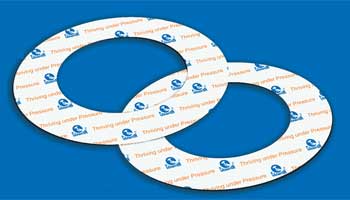

Champion PTFE Solutions - e-PTFE Sheets

Certification

It does not support bacterial growth or cause product contamination and is FDA 21 CFR 177.1550 certified

- High adaptability, suitable for flanges with corrosion and with uneven sealing surface.

- Ideal for use with more fragile piping systems

- Easy to install and remove, anti-sticking for effortless flange surface cleaning.

- No embrittlement of the gasket in storage or in service.

- FDA certified.

- Impermeable.

- Chemically inert.

- High temperature and pressure.

- Seals at low stress loads.

Physical Properties :

| Description | Industrial grade |

| Length Tensile Strength | 17.0MPa |

| Cross Tensile Strength | 27.0MPa |

| Compressive Strength | 14.7MPa & Max : 20.0MPa |

| Temperature | upto 260。C |

| Density | 0.80-0.95 g/cm3 |

Available in 3 sizes- 1500mm x 1500mm - S1 , 1500mm x 3000 mm - S2 and 1500mm x 4500mm - S3 Thickness- 0.5mm , 0.8mm, 1mm , 1.5mm , 2 mm , 2.5mm , 3mm , 4mm , 5mm , 6mm & 6.5 mm

Search

Search Contact

Contact